1

/

of

1

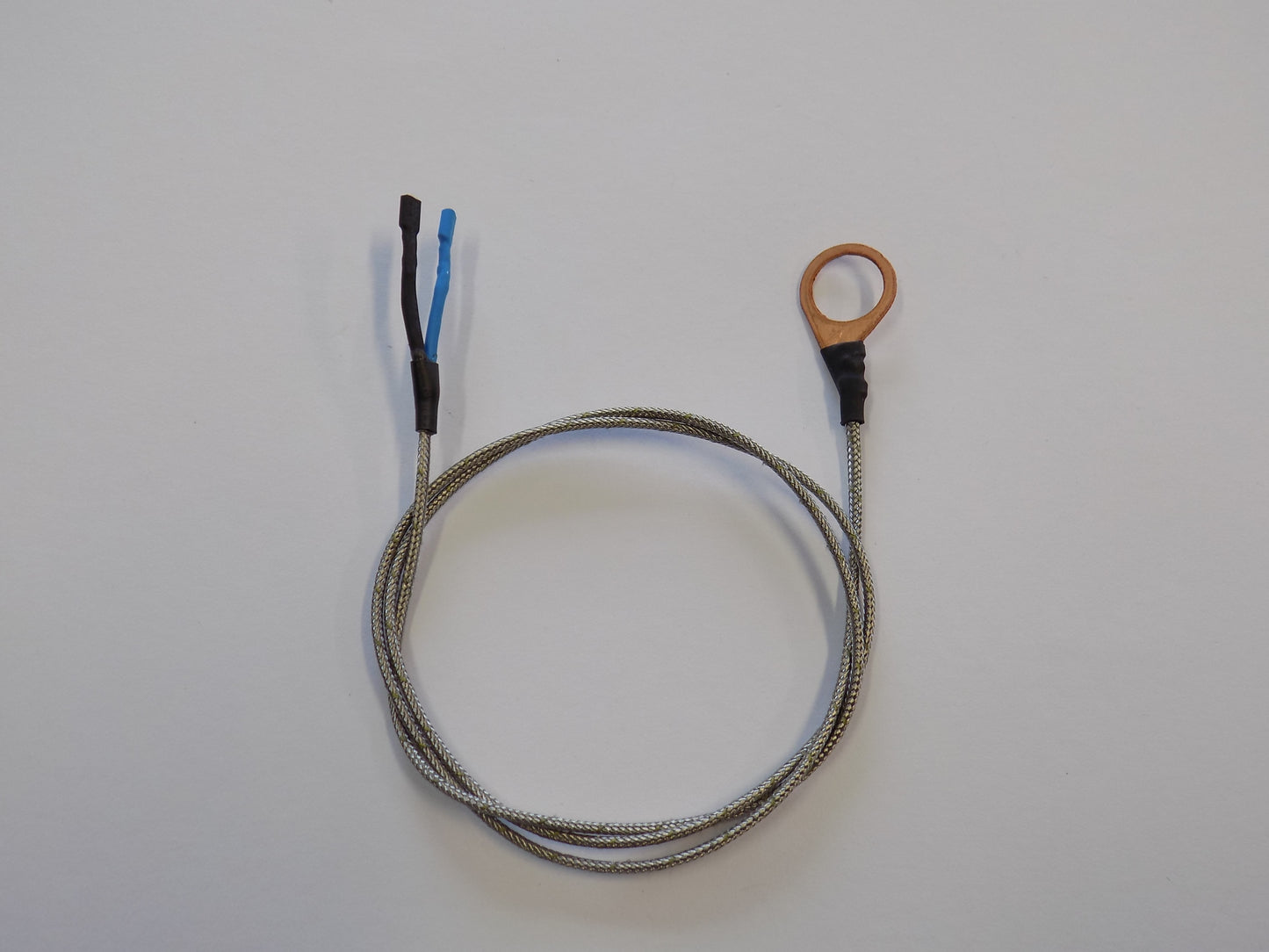

CHT Sensor

CHT Sensor

Fly Henry

Regular price

£40.00 GBP

Regular price

Sale price

£40.00 GBP

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

The Fly Henry CHT (Cylinder Head Temperature) Sensor is a precision temperature probe specifically designed for use with Fly Henry engine monitoring systems (such as the PPG Meter and FLY Meter) and other compatible digital avionics.

These sensors are primarily used in microlight, paramotor, and experimental aircraft engines (like Rotax, Simonini, and Vittorazi) to monitor head temperatures and prevent overheating.

1. Core Types & Mounting

Fly Henry typically offers two main mounting styles for their CHT sensors:

- Ring Terminal (Under-Plug): This is the most common type for Fly Henry systems. The sensor is a flat copper or brass ring that sits directly under the spark plug.

- 14mm Ring: Standard for most 2-stroke engines (Rotax 503, 582, etc.).

- 12mm Ring: Standard for 4-stroke engines (Rotax 912) or smaller spark plug variants.

- Bolt-On / Drill Type: A smaller ring (usually 10mm) designed to be secured under a cylinder head bolt rather than the spark plug itself.

2. Technical Characteristics

-

Sensor Element: Fly Henry uses J-Type Thermocouples for their CHT sensors.

- Note: Ensure your instrument (e.g., IFD-NET or Fly Meter) is set to "J-Type" as K-Type sensors use different voltage-to-temperature curves.

- Temperature Range: Typically rated from 0°C to 1000°C (though CHTs rarely exceed 250°C, the thermocouple wire itself is high-heat resistant).

- Cable Options: * Standard lengths are usually 50 cm or 80 cm.

- The "New Model" (2024 onwards) usually features a 50 cm black lead with a specialized connector for the Fly Henry Measurement Module.

- Construction: The leads are often protected by a high-temperature silicone or glass-fibre sleeve to resist engine vibration and heat.

3. Installation & Maintenance

- Spark Plug Torque: When using the ring-type sensor, you must ensure the spark plug is torqued correctly. The sensor acts as a washer; if it's too thick or improperly seated, it can cause a compression leak.

- Lead Routing: The wires should be routed away from the exhaust manifold. While the sensor is heat-resistant, constant contact with an exhaust pipe will eventually melt the insulation and cause a short (which usually results in the gauge showing a maximum or "off-scale" reading).

-

Shortening Wires: You can shorten the wires, but you should not extend them with standard copper wire. Doing so creates a "second junction" that will introduce significant temperature errors. Always use J-Type extension wire if needed.

4. Compatibility with IFD-NET / EVO EMS

If you are using a Fly Henry CHT sensor with an IFD-EVO EMS Full:

Shortening Wires: You can shorten the wires, but you should not extend them with standard copper wire. Doing so creates a "second junction" that will introduce significant temperature errors. Always use J-Type extension wire if needed.

-

- The EVO EMS is generally configurable for various sensor types. You must select the J-Type Thermocouple profile in the instrument settings to get an accurate reading.

- Fly Henry sensors are popular because they are often more affordable than "certified" Rotax or VDO probes while offering similar accuracy for the experimental sector.

Share